Transparent resin 3D printing materials

Transparent resin 3D printing material is a kind of low viscosity liquid photosensitive resin, strong, tough, water resistance, some similar to ABS material.These printed parts can be polished, painted, and sprayed, and when polished on both sides, they are closer to colorless and look more like real, clear engineering plastics

Technical parameters of 3D printing

1, a molding printing size: 600x600x400mm;

2, printing layer thickness: 0.05mm~0.25mm;

3, attainable accuracy:

Molding accuracy: ±0.1mm (L≤100mm) or ±0.1%×L (L > 100mm)

4, post-processing: easy polishing, spraying, electroplating, drilling, can join large size objects;

Characteristics

It is a kind of low viscosity liquid photosensitive resin, strong, tough, water resistance, some similar to ABS material.These printed parts can be polished, painted, and sprayed, and when polished on both sides, they are closer to colorless and look more like real, clear engineering plastics

Mechanical properties

| Technical performance | The test method | The metric system |

| The tensile strength | ASTM D638M | 47.1 – 53.6 MPa |

| Elongation at break | ASTM D638M | 11 – 20 % |

| Yield elongation | ASTM D638M | 3.3 – 3.5 % |

| Modulus of elasticity | ASTM D638M | 2,650 – 2,880 MPa |

| Poisson’s ratio | ASTM D790M | 63.1 – 74.2 MPa |

| The bending strength | ASTM D790M | 2,040 – 2,370 MPa |

| Bending modulus | ASTM D256A | 0.2 – 0.3 J/cm |

| Ehrlich impact strength, notch | ASTM D542 | 1.512-1.515- |

| Hardness | ASTM D2240 | N/A |

| Graves tear | ASTM D1004 | 150,288 N/m |

| Bibulous rate | ASTM D570-98 | 0.35% |

Thermal and electrical properties

| Technical performance | The test method | The metric system |

| C. T. E. -40°C – 0°C | ASTM E831-00 | 66 – 67 μm/m-°C |

| C. T. E. 0°C – 50°C | ASTM E831-00 | 90 – 96 μm/m-°C |

| C. T. E. 50°C – 100°C | ASTM E831-00 | 170 – 189 μm/m-°C |

| C. T. E. 100°C – 150°C | ASTM E831-00 | 185 – 189 μm/m-°C |

| The dielectric constant is 60Hz | ASTM D150-98 | 3.1 |

| The dielectric constant is 1 kHz | ASTM D150-98 | 3.5 |

| The dielectric constant is 1MHz | ASTM D150-98 | 3.1 |

| Dielectric strength | ASTM D149-97a | 15.4 – 16.3 kV/mm |

| Glass transition temperature Tg | ASTM D1545-00 | 39 – 46 °C |

| Thermal deformation HdT @ 0.46MPa | ASTM D648-98c | 45.9 – 54.5 °C |

| Thermal deformation HDT @ 1.81MPa | ASTM D648-98c | 45.9 – 54.5 °C |

About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

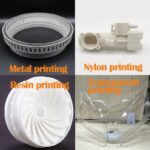

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.