About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

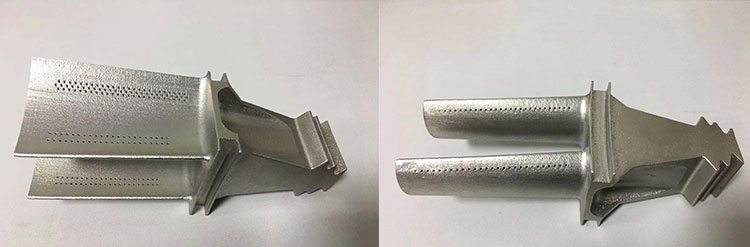

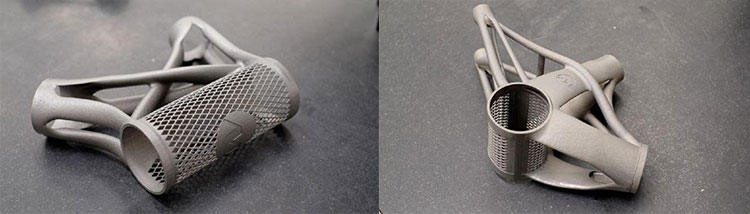

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.