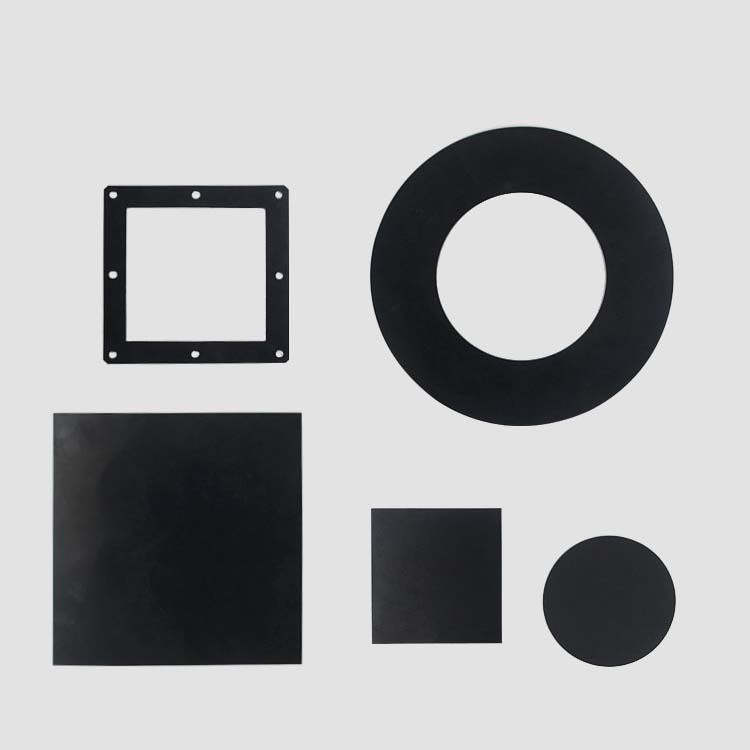

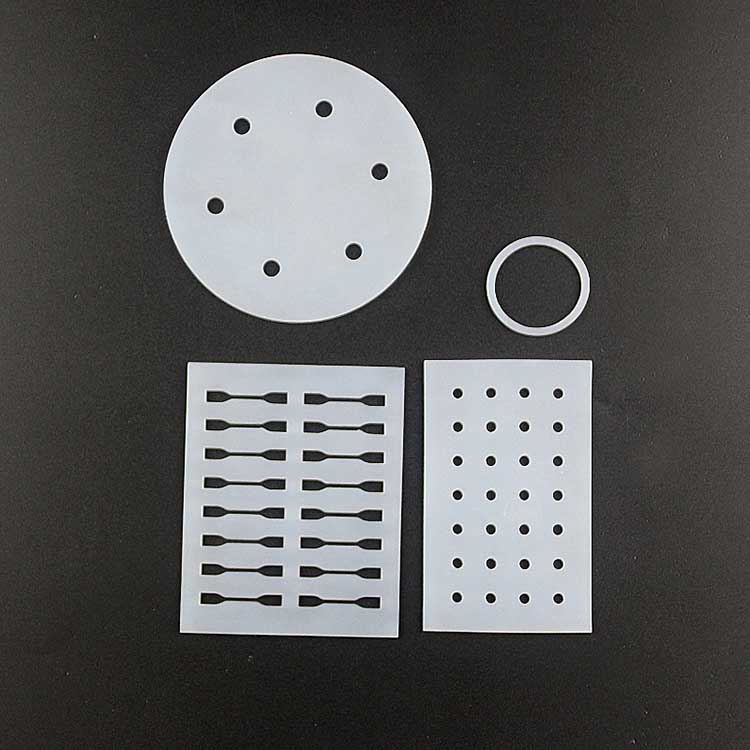

Rubber/Silicone parts processing custom production

We are a professional rubber/silicone parts processing custom manufacturers, to provide customers with all kinds of soft rubber products customized processing services.

Rubber is divided into natural rubber and synthetic rubber, the structure of natural rubber is a high polymer of isoprene, synthetic rubber such as butadiene rubber, neoprene rubber, butadiene rubber and so on. Silica gel as a kind of rubber, with high and low temperature resistance, weather resistance, ozone resistance, non-toxic environmental protection and other characteristics. Silicone and rubber can not say which good, can only say that the application in the right way.

The difference between rubber and silicone

Rubber is divided into natural rubber and synthetic rubber, the structure of natural rubber is a high polymer of isoprene, synthetic rubber such as butadiene rubber, neoprene rubber, butadiene rubber and so on. When the crosslinked rubber is deformed by external force, it has the ability of rapid recovery, and has good physical and mechanical properties and chemical stability.

Silicone rubber is mainly composed of high molar mass linear polysiloxane. Because si-O-Si bond is its basic bond type, silicon atoms are mainly connected with methyl groups, and a very small amount of unsaturated groups are introduced on the side chain. The intermolecular force is small, the molecules are spiral structure, and methyl groups are arranged outward and can rotate freely. Therefore, silicone rubber vulcanization has excellent high and low temperature resistance (-100~315℃). Weather resistance, hate water, electrical insulation, physiological inertia and other characteristics, in the national defense, medical and health, industrial and agricultural production and People’s Daily life has been widely used. Most importantly, it is not toxic and is commonly used in things like pacifiers and breast implants.

1. They have different definitions. Rubber is a general term, including many kinds, such as natural rubber, butadiene rubber, styrene butadiene rubber, propylene rubber, of course, also includes silicone rubber; And silica gel is one of the specific varieties of rubber.

2, rubber is widely used, mainly using the elastic effect of rubber, such as rubber tires, bridge shock absorption, rubber hose cots, mainly in industrial use; Silica gel is mostly used in food and household appliances, such as pacifiers, children’s spoons, voltage pot sealing and so on.

3, different types and grades of rubber applications are not the same, such as natural rubber is mainly used for tires, butyl rubber is mainly used for inner tubes, epDM rubber for sealing products.

4, in the selection of rubber, need to be based on specific performance indicators, such as hardness, tensile strength, compression deformation, wear, tear, use environment, etc.. From their properties, we can see that silicone rubber has incomparable advantages of ordinary rubber. The price of silicone rubber is more expensive, which is better depends on our use. If ordinary rubber products can meet our needs, there is no need to kill a chicken with a knife, the use of silicone with better performance and higher price.

About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.