Blog

Metal 3D Printing Technology And Principle

Metal 3D printing technology can be roughly divided into two main categories: Powder bed fusion (PBF) technology and Directed energy deposition (DED) technology.Both of these technologies can be further classified according to the type of energy used.In PBF, thermal energy selectively melts the powder layer region.The main agents of PBF are Selective Laser Sintering (SLS), Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS) and Electron beam Melting (EBM).In DED, the deposition is made by using focused heat to melt the material (powder or filament).Some commonly used DED technologies include Laser engineered net shaping (Lens), Direct metal deposition (DMD), Electron beam free form fabrication (EBFFF), and arc additive manufacturing.Currently, the following three technologies are used in commercial metal 3D printing:

1) Selective Laser Melting (SLM)

2) Direct Metal Laser Sintering (DMLS)

Selective laser melting (SLM) and direct metal laser sintering (DMLS) are two additive metal manufacturing processes belonging to powder bed fusion 3D printing family.The two technologies have many similarities: Both use a Yb (ytterbium) fiber laser to scan and selectively melt (or melt) metal powder particles, glue them together and build the parts layer by layer.Direct metal laser sintering (DMLS) is a kind of high energy laser beam (200 W), according to the 3D model data directly sintered metal powder thin layer (20~60 μm) to form a dense solid parts,DMLS and SLM basically the same principle, the main difference lies in the nature of the powder.

Technology principle :SLM technology is a kind of technology which uses metal powder to be completely melted and solidified by cooling under the thermal action of laser beam.Before the start of the laser beam scanning using roll shop powder evenly on the forming cylinder on the substrate of a very thin layer of metal powder, computer control to the current layer for laser beam selective laser melting, molten metal powder after cooling solidification, forming cylinder to reduce the height of a unit, powder cylinder climbing a unit level, spread powder roller on processed slice layer to spread good metal powder, a new layer, start scanning laser beam so layer upon layer overlay, until the entire component forming.The entire process of the SLM is carried out in a processing chamber protected by inert gas to prevent oxidation of metals at high temperatures.

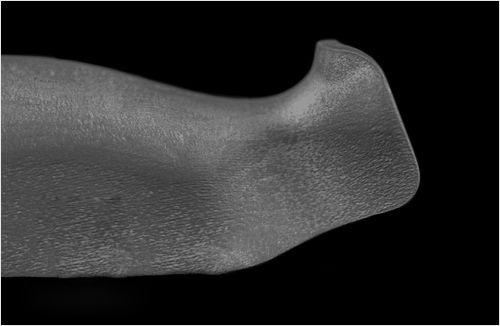

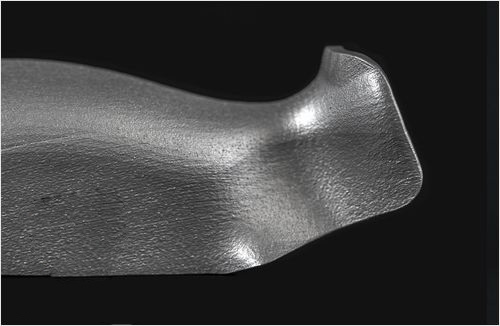

DMLS: Through the use of high energy laser beam and controlled by 3D model data to partially melt the metal matrix, at the same time sintering solidified powder metal material and automatically stack layer upon layer, to generate dense geometric solid parts.DMLS is metal powder forming, there are two types of coaxial powder and roller powder feeding.Coaxial powder feeding technology is suitable for the manufacture of layered thickness in more than 1mm objects, large metal parts.Roller powder feeding products have high fineness and are suitable for the manufacture of small parts, because parts are easily heat deformed during the manufacturing process.SLM- Metal 3D Printed Sample

CAD 3D solid parts model is drawn on the computer, which is converted into STL file format, and then the file is cut into a series of ordered slices with a certain thickness by slicing software.Before the start of sintering, the metal powder is preheated to a temperature lower than the sintering point, one side of the powder cylinder rises to the feeding amount, the powder roller will be evenly spread on the surface of the powder bed, laser beam under the control of the computer system, according to the set power and speed of the first layer of the cross-section profile for scanning.After the laser beam is swept, the powder is sintered into a solid outline sheet of a given thickness, supported by the unsintered powder, so that the first layer of the part is sintered.At this time, the powder bed moves down a layer thickness, the powder cylinder moves up, the powder roller re-lays the powder, the laser beam for the next layer of sintering, before and after the sintering of the solid sheet naturally bonded as a whole, so the cycle is repeated and stacked layer by layer until the sintering of the three-dimensional solid parts is completed.

3) Electron beam melting technology (EBM)

Electron beam melting (EBM) is another additive manufacturing process based on PBF. In the vacuum environment, high energy and high speed electron beam is used to selectively melt metal powder layer or wire, melt and form, and stack layer by layer until the whole solid metal parts are formed.The tungsten wire heated in the EBM emits high-speed electrons, which are then controlled by two magnetic fields, the focusing coil and the deflecting coil.The focusing coil acts as a magnetic lens to focus the beam to the desired diameter of 0.1mm, while the deflecting coil deflects the focused beam at the desired point to scan the metal powder.When an electron hits a metal powder at high speed, its kinetic energy is converted to heat energy, melting the metal powder.Electron beam fusion 3D-printed samples

Technical process principle: after the platform is heated to a certain temperature, the metal powder is uniformly spread on the platform according to the preset thickness. Each powder layer is scanned into two stages: preheating and melting.In the preheating stage, the final layer of powder was preheated several times by using a high scanning speed high electron beam (preheating temperature up to 0.4~0.6Tm).In the melting phase, a low electron beam with a low scanning velocity is used to melt the metal powder.When the first layer is scanned, the table is lowered, the metal powder layer is re-laid, and the process is repeated until the desired metal part is formed.The whole EBM process is carried out at a high vacuum of 102~103 Pa.

Metal 3D printing materials: stainless steel 316L, aluminum alloy, die steel MS1, titanium alloy TI64, high temperature alloy, aluminum magnesium alloy AlSi10MG, nickel alloy IN718, bronze precious metal, etc

Design rules for metal 3D printing

1) Thickness of chamber wall

In 3D printing, wall thickness is the distance between one surface of the model and the opposite transparent surface.Usually the minimum wall thickness you can use is 1 mm.The applicable minimum wall thickness may vary depending on factors such as the geometry and size of the part.There is no maximum wall thickness, but keep in mind that thicker areas may increase stress on the part, which may cause deformation and may lead to an unstable build process.

2) Details size

Very fine details (as small as 0.5mm) can be obtained when printed using metal 3D printing (M3DP).The detail size refers to the distance between the model surface and the detail surface.Letters are also considered details, but their size depends on whether they are carved or embossed.For engraving text or surface details, we recommend a minimum line width of 0.4 mm, a minimum total height of 0.4 mm, and a minimum depth of 0.15 mm.For embossed text or surface details, we recommend that the lines of the letters be at least 0.4 mm thick, the overall height be at least 0.4 mm, and the depth be at least 0.15 mm.

3) Surface quality and orientation

The direction in which a part is stacked has a significant impact on surface quality because it defines the direction of the part surface relative to the horizontal plane or bottom plate.Angles less than 45° (β) measured relative to the build plate tend to result in poorer surface quality, while steep angles greater than 45° may have a better, smoothier surface.Overhanging structures (such as the underside of a table) may have poor surface quality.

4) Thermally induced stress

You do metal 3D printing on a 3D model, which is basically a layered welding process.Delaminated powder melting and its curing results in thermally induced stress as the melted powder cools.A design that is not suitable for the M3DP may result in build failure and/or component deformation due to large thermal stresses.Therefore, process-specific limitations must be considered when designing parts.We recommend that you round or corner the edges in your design, with a minimum radius of 3 mm.Also, avoid sharp edges for the same reason.Try to avoid large amounts of material accumulation and generally favor organic shapes with edge designs

5) Dimensional accuracy

Dimensional accuracy is independent of the details of the model, but independent of the deviation of the nominal measurement.The general accuracy of 3D printing is ± 0.2% (lower limit is ± 0.2mm).Please note that shape deviations may also occur due to designs that do not conform to prohibited book D printing (M3DP) and high thermal stresses.

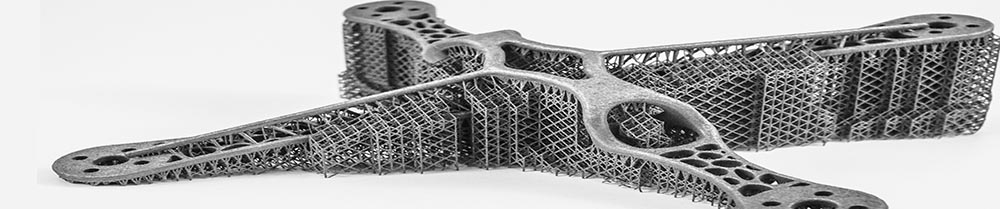

6) support

Metal 3D printing (M3DP) is a layered manufacturing process.The widget is built layer by layer from digital files.Depending on the orientation of the part surface, support structures may be required and these must also be printed during the manufacturing process.The support structure allows your model to be rigidly connected to the build platform during the printing process and absorbs internal stress, while also preventing part deformation.It is often necessary to support walls or overhangs with a measurement Angle lower than 45° relative to the build platform, otherwise it will result in build errors.After the part is successfully constructed, the support is removed and the part is sandblasted.Some traces of the removal of the support structure may still be visible.

7) Powder removal

When making hollow models, it is important to include at least one hole in the design so that any unused powder contained in the cavity can be removed.Try to use a minimum wall thickness of 1 mm and keep at least one opening with a minimum diameter of 3 mm.The opening will be used as an outlet for unused powder in the trapped print part.Large and complex cavities require multiple holes with larger diameters, preferably 7mm.The holes in the center of the model are usually best because they remove most of the powder.Powder traps in hollow areas must be avoided so that the powder in the hollow areas can be completely removed.

4, metal 3D printing post-processing effect: grinding, polishing, sandblasting, matte, bright treatment.Welcome to consult!