Blog

A new material inspired by human bones could be made stronger by vibrations

Whether it’s a structural beam supporting an apartment building or a piece of scotch tape supporting a school science project, we’re used to materials getting weaker over time, but a New invention from the University of Chicago may be changing that, according to New Atlas.Inspired by the way our bones adapt to their mass and strength to support different loads over a lifetime, engineers have developed a new type of gel that actually intensifies vibration and pressure over time. 3d printing service

“Every other material is weaker when it vibrates,” said Aaron Esser-Kahn, who led the research team.”This is the first time we have reversed this process, showing that a material can strengthen itself by mechanical vibration.”

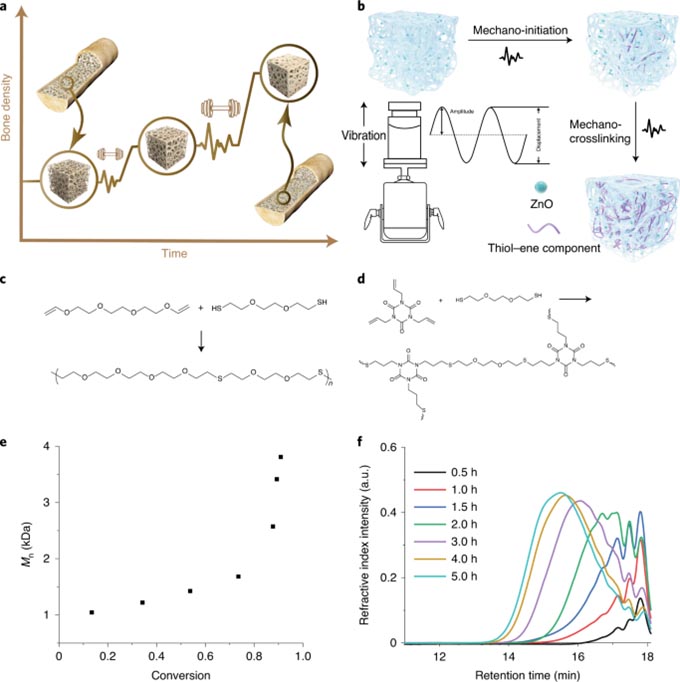

While some of the inspiration for Esser-Kahn and his team came from the adaptations of human bones, another part came from the so-called piezoelectric effect.This refers to devices and materials that can accept mechanical stresses and vibrations and convert that motion into electrical charges.We’ve already seen how the technology can be incorporated into shoes, roads and laptop keyboards, but the UC team describes this particular application as a first.

The initial idea was that it might be possible to use the charge generated by the piezoelectric effect to trigger reactions inside the material, thereby increasing its strength.So they began experimenting with different chemicals in an effort to produce a gel with the right properties.After working through dozens of mixtures, the team finally found a “winner” : a polymer gel composed of a mixture of so-called mercaptan reactants and piezoelectric particles of zinc oxide.

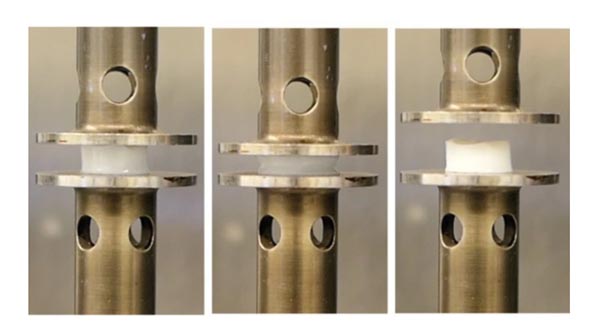

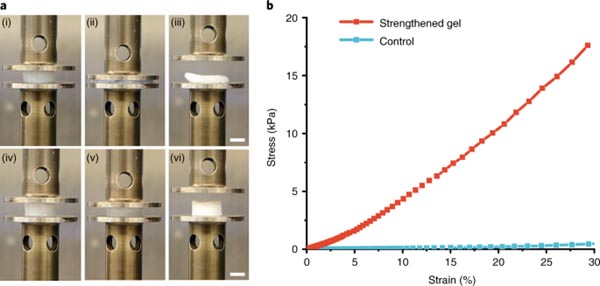

The material can be vibrationally strengthened because the particles can transfer energy and trigger a mercaptan reaction that creates a new crosslink in the material.In tests, the team turned the soft gel into a material that was nearly as rigid as the inside of the bone, making it 66 times stronger just by subjecting it to vibrations.Interestingly, the material strengthened more where it was subjected to the greatest stress.

“Just like the bone, the strength of the material is exactly the same as the force we put in.”Esser – Kahn said.

The team sees many possibilities for this type of material, including buildings that become stronger over time, or medical implants that integrate more effectively with the body.One really promising area is adhesives, such as those used in aerospace engineering to fuse different materials together.

“There could be a huge impact on adhesives,” Esser-Kahn said.”Adhesives are almost always the point of failure in the material.This may lead to specialized adhesives that are stronger and set better.”