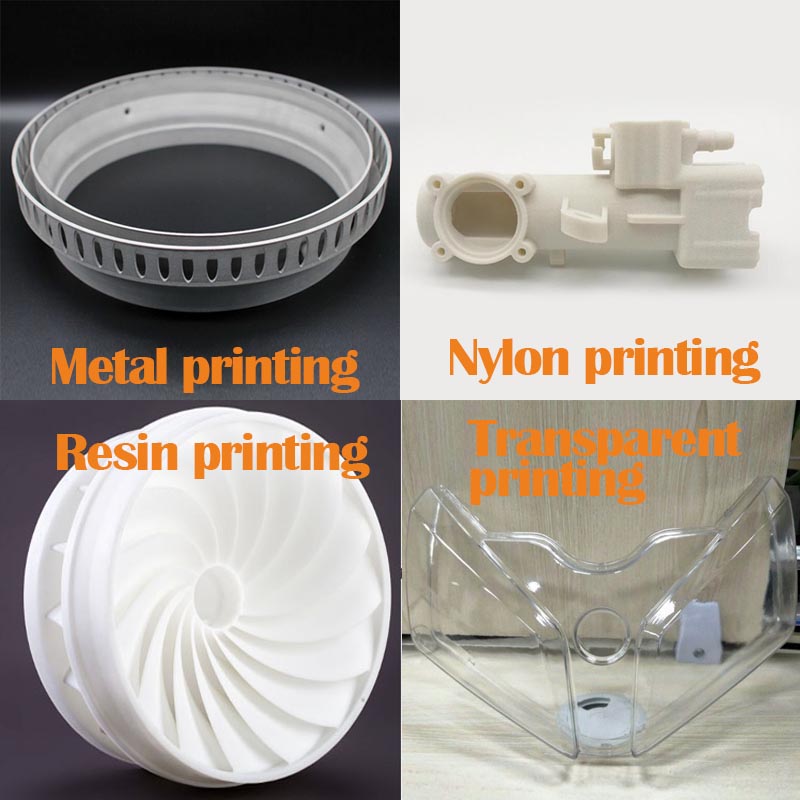

Metal/Plastic 3D printing services for industrial parts processing production

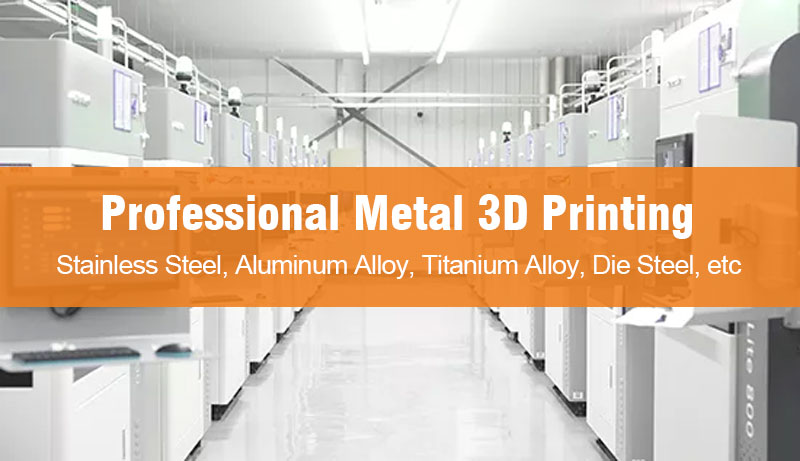

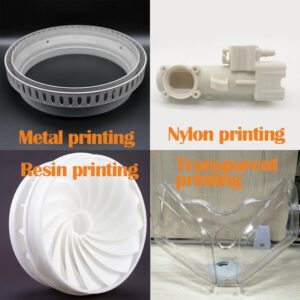

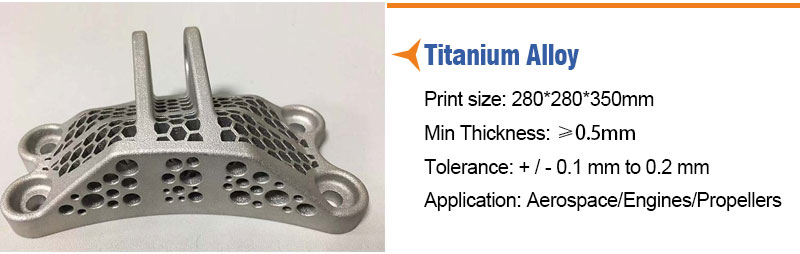

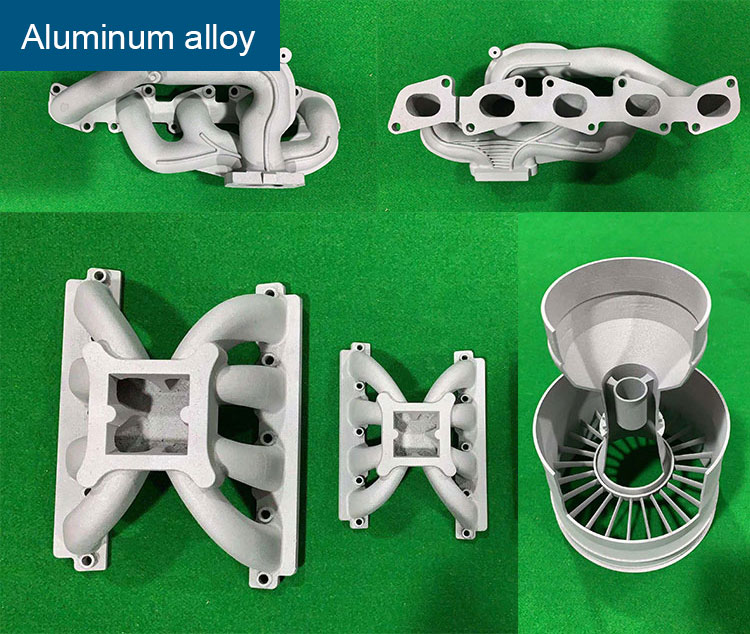

Metal 3D printing service printing materials: stainless steel, aluminum alloy, titanium alloy, mold steel, etc., please contact us for free quotation.

Describe

Metal 3D printing service can print all kinds of metal materials, including stainless steel, aluminum alloy, titanium alloy, mold steel, tin bronze and so on.The metal printing surface has particle sensitivity, tolerance ±0.2mm;

Printing process

1. Contact us and send your drawings (STL/OBJ/STP/IGS/PRT, etc., as long as they are 3d software modeling files) with your detailed requirements;

2. According to your requirements, we recommend materials and calculate the lowest price;

3. Confirm the price and arrange the payment;(T/T or PayPal)

4. We arrange production and report the progress to you throughout the process;

5. After the production is completed, I will take photos or videos for your confirmation;

6. Arrange express delivery;

7. After you receive the express, confirm that the parts are ok;If you have any questions, please feel free to contact us for consultation.

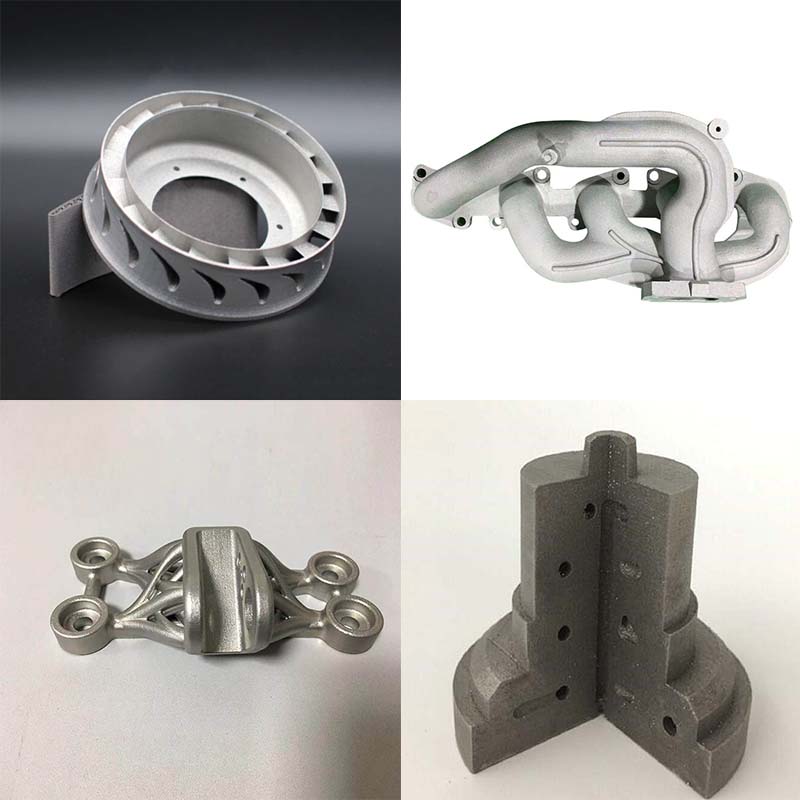

Product display

Design rules for metal 3D printing

Ventricular wall thickness

In 3D printing, wall thickness is the distance between one surface of the model and the opposite transparent surface.Typically you can use a small wall thickness of 1 mm.The applicable small wall thickness may vary depending on factors such as the geometry and size of the part.This has no wall thickness, but keep in mind that thicker areas may increase the stress on the part, which may cause deformation and may lead to an unstable build process.

5 applications of 3D printing in the automotive industry:

Used for design;

Direct production of complex parts;

The production of lightweight structural parts on the automobile;

Customized workpieces and testing instruments;

The production of vehicle model;

Rozeem offers a transformational opportunity for metal parts production.

Precautions for Metal 3D Printing: If you are a new contact with metal 3D printing process, please read the following carefully

1: It is recommended to tap the thread, not to print directly (including internal and external threads)

2: the wall thickness less than 0.5mm does not guarantee that it can be printed

3: Assemble parts need to be reminded to send the assembly drawing, which will be sent out after the assembly is completed before delivery. If there is no reminder, no assembly is required, and 0.15mm should be placed on one side of the gap of the product to be assembled

4: high requirements for local assembly (such as bearing hole/diameter/plane assembly) to set aside processing allowance in advance, and then through the secondary finishing with

5: metal printing after high temperature sintering some slender, thin-walled parts, shell and other structures will be deformed, metal printing advantage is complex structure, precision and surface effect is inferior to machining

6: natural color surface pitting (about RA7)

7: accuracy plus or minus 0.1mm or so

8: metal printing material processing: the same as traditional materials can be subsequent secondary processing metal printing materials: the metal printing more mature materials include titanium alloy (TC4), aluminum alloy (AlSi10Mg), stainless steel (316 l), steel (1.2709) used to sample parts, stainless steel and aluminum alloy die steel is often used in mold shaped waterways, the price also very cheap.

About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

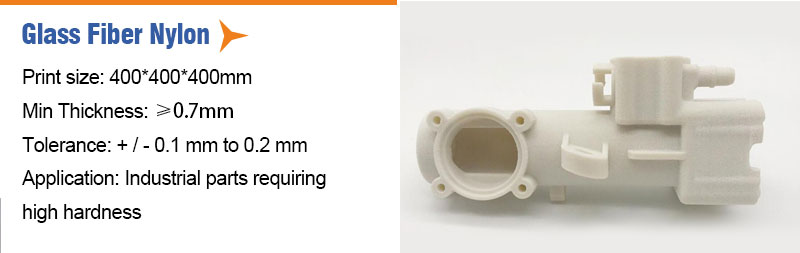

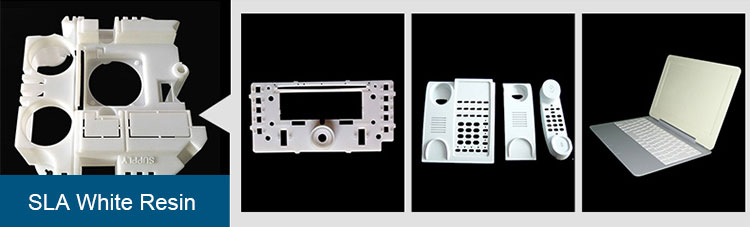

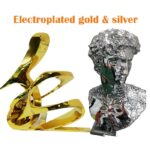

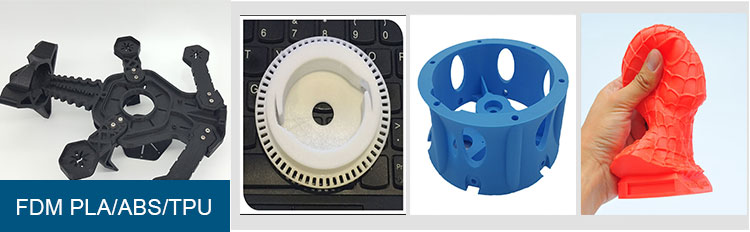

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.