Blog

Brief analysis of the characteristics of five commonly used 3D printing materials

If you want to choose suitable materials for your own 3D printer, you must first understand the characteristics of 3D printing materials. Each 3D printing material has different characteristics, so you should first consider the material characteristics of the product you need, then select suitable materials and print accordingly.Here are five commonly used 3D printing materials.

Photosensitive resin: the printing accuracy of this material is the highest, usually can do 0.05mm.The surface is also very smooth, suitable for printing appearance parts, and it is also the only choice for 3D printing to check the size of die opening.Can be divided into two kinds of common resin and toughness resin.Ordinary resin is white, weak strength, easy to break, over a long time will turn yellow, so if it is the appearance of the best is to do color processing.Tough resins are usually emerald green or light yellow.Compared with ordinary resin, toughness resin strength is slightly better, not easy to break.It is worth mentioning that: resin material to make structural parts, do not tap the thread above, also do not use tight collocation way to place the nut, the hole will explode.

PLA: The printing cost of this material is relatively low. If we do temporary structural display, we can use this material to make it without high requirements on appearance.The material strength is high, the printing process can also be very convenient to optimize the filling rate inside the structure, so it is very easy to achieve lightweight.Accuracy is slightly weak, if the parts have collocation relation, must put aside enough gap to ensure assembly.Usually the axle hole collocation should leave at least 0.5mm gap.When designing, the suspended structure should be reduced as far as possible, because the suspended structure part needs to print support, which will be relatively rough.The material deformation temperature is 60 degrees, cannot be used in high temperature environment.

TPU: Soft plastic material, rich colors, can print wheels, shock cushions, sealing rings and other parts.Hardness between 80A and 95A.The printed surface of the finished product is bright and clean.The parts with complex structure are drawn seriously after printing, and the surface is hairy, which is difficult to clean.If the surface requirements are very high can also be done in the way of duplex mold, it is to print out the resin prototype, and then wrapped with silica gel, to make the mold, and finally to make the TPU parts with similar casting method, the process is more complex, the production cost is high, the effect is good, can do watchband and other complex parts.

ABS: a common engineering plastic, with heat resistance, impact resistance, low temperature resistance, chemical resistance and good electrical properties, product size stability and other characteristics.The thermal deformation temperature is 93-118 ℃, and it can still show a certain toughness at -40℃. It can be applied in the temperature range of -40℃ to 100℃.Suitable for making structural parts.

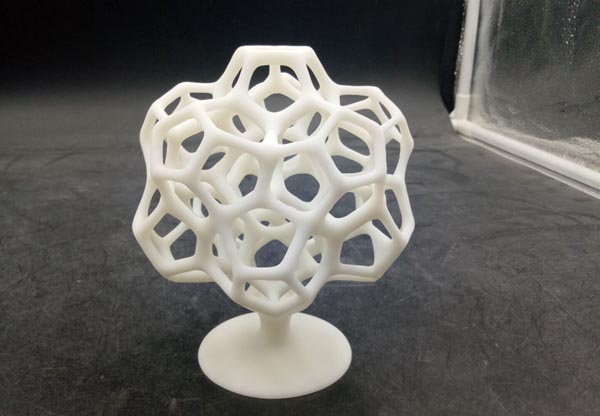

Nylon: Nylon is one of the strongest nonmetallic printing materials.At this stage, the best process for printing nylon is SLS laser powder sintering. The forming accuracy is very high, and the strength and toughness of the workpiece obtained are also the best. In addition, the nylon material itself is also high temperature resistant, wear-resistant, and suitable for structural framework.After laser sintering, the surface of the parts has its own frosted texture, which can be done without surface treatment.