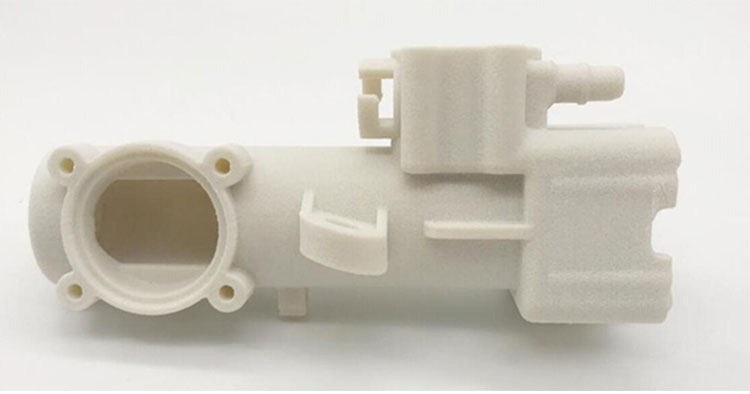

Glass Fiber Nylon PA3200GF 3D Printing Material

The excellent long term unchanging type of fiberglass nylon PA3200 GF material is used in the last part of the engine area such as automobiles, for deep drawing molds or any other applications requiring specific stiffness, high thermal deformation temperature and low wear.

Technical parameters of 3D printing

1, a molding printing size: 700x380x580mm;

2, printing layer thickness: 0.06mm~0.18mm;

3, attainable accuracy:

± 0.15mm (Accuracy depends on geometry.It varies according to product size, printing and post-processing methods.;

4, later processing: can be high temperature dyeing, metal spraying, drilling;

Characteristics

PA3200 GF is a white, glass-filled polyamide 12 powder that is characterized by excellent rigidity in combination with good elongation at break.Laser sintered parts made from PA3200 GF have excellent material properties:

High stiffness,

• High mechanical wear resistance

• Good thermal load capacity

• Excellent surface quality

• High dimensional accuracy and detail resolution

• Good processability

A typical application of the PA3200 GF is to use the last part of an engine area such as an automobile, for deep drawing molds or any other application requiring specific stiffness, high thermal deformation temperature and low wear.

| Technical performance | The test method | The metric system |

| The tensile modulus | ISO 527-1/-2 | 3,200 MPa |

| The tensile strength | ISO 527-1/-2 | 51MPa |

| Elongation at break | ISO 527-1/-2 | 9% |

| The impact strength | ISO 179/1eU | 35J/cm |

| Notch Impact Strength (+23°C) | ISO 179/1eA | 5.4J/cm |

| The bending strength | ISO 178 | 73 MPa |

| Bending modulus | ISO 178 | 2,900 MPa |

| Cantilever notched impact (23°C) | ISO180/1A | 4.2J/cm |

| Nodged beam impact strength No notch (23°C) | ISO180/1U | 21J/cm |

| Shore D Hardness (15S) | ISO 868 | 80 |

| Ball indentation hardness | ISO2039-1 | 98 |

| Melting temperature (20°C/ min) | SO11357-1/-3 | 176°C |

| Thermal deformation HDT @ 0.45MPa | ISO75-1/-2 | 96°C |

| Thermal deformation HDT @ 1.80MPa | ISO75-1/-2 | 157°C |

| VEKA softening temperature (50℃/ h 10N) | ISO306 | 179°C |

| VEKA softening temperature (50℃/ h 50N) | ISO306 | 166°C |

About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.