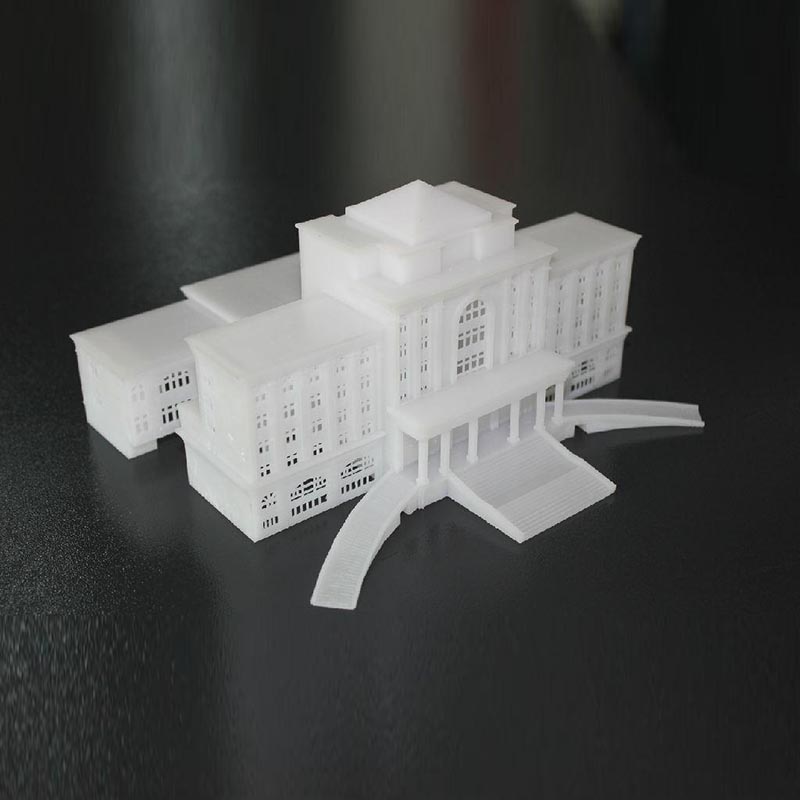

Perfect Application of 3D Printing Building Models

3D printing of architectural models has been accepted by more and more people in the industry for its fast, low cost and environmental protection, as well as its exquisite production and saving a lot of materials.

Architectural sand table model represents architectural art in the form of miniature entity, faithfully expresses the structure of architectural thought, and transforms the intention of architects into concrete images.3D printing of architectural models has been accepted by more and more people in the industry for its fast, low cost and environmental protection, as well as its exquisite production and saving a lot of materials.

The architectural model is very important, thus enabling the client to visualize the full version of the proposed project.However, the process of making traditional architectural models is very hard and labor-consuming.It is particularly difficult, time-consuming, and expensive to reproduce exactly the details of a reduction.As a result, small details that are very important are often given up, but often the distinction between a particular design and the customer’s decision-making process can have a negative impact.The high level of detail is very important to the user.It’s the difference between keeping those details and losing them.

Using 3D rapid prototyping can cut down on the manpower and time required to create detailed, accurate scale models that effectively convey the unique concept of each design to the client.They are able to replicate fine-scale design elements very accurately and in a short amount of time, at a fraction of the cost of a hand-built model.Made of rugged, durable materials, the model walls can be up to 0.6mm thin and intricate details are unexpectedly strong.

Materials for 3D printing of building models: The materials used for building models are mainly polylactic acid (PLA), ABS resin, light curing photosensitive resin and thermoplastic (PA nylon powder), etc. The 3D printing technologies are FDM fuse manufacturing technology, SLA light curing rapid prototyping technology and SLS selective laser sintering technology respectively.

There are three main types of 3D modeling software for architectural models: (1) conventional animation software Maya, 3DMax and Rhino;② Building Information Modeling (BIM) modeling software Revit, Archi CAD, Bentley;③ Basic drawing software Auto CAD.SketchUp, an open source 3D mapping software, is also ideal for building models.

3D printing of architectural model 3D data requirements: in addition to the first to meet the requirements of 3D printing technology sealed physical documents.Also note the following adjustments to the model:

Before the modeling work of the architectural model is completed and output printed, it is also necessary to adjust the size of the detailed components, split the model and assemble the model according to the performance of the 3D printer equipment and the selected printing materials, so as to ensure the realization of the final use requirements.Due to different 3D printing molding technologies and 3D printing materials, there are requirements for minimum wall thickness and later cleaning or support removal. The wall thickness is too small, and the components are easy to be damaged in the process of cleaning.

1. Adjust the facade model, sometimes the model to be printed is beyond the size of the 3D printer at one time, while the model should reflect the architectural details. If the print size of the model is too small, many details of the lines are difficult to show the effect.According to the way of block printing group to achieve the final model printing effect.In the split as far as possible to choose the vertical or horizontal lines of the facade, so that the later stitching joint will not affect the overall effect of the model.In order to reduce the amount of materials used, the outer wall of the building is generally printed with a thin thickness. Considering the model splicing and preventing deformation, a connection component with a certain strength should be designed at the splicing part to ensure the compact assembly and integrity of the model.

2, model detail component processing, when the building model compared to the smaller dozens or even hundreds of miniature model, some details (such as: pillars, window frames, glass strength, railings and other exposed details) will become very thin and thin, it is impossible to support or clear powder.Therefore, some details of the model should be enlarged appropriately according to the requirements of the minimum wall thickness size and diameter.Only then can meet the requirements of post-printing and cleaning powder.

3. Adjust the indoor model. The size adjustment method of the indoor model component is basically the same as that of the facade model component, which shall meet the requirement that the size calculated after the component is scaled down in proportion is greater than the minimum wall thickness of the printer.When adjusting the size of indoor walls, the proportion between different walls should be taken into account, and the mutual proportion between walls should be as close as possible to the real situation.In order to clear the powder or support, the vertical and horizontal components should be split before printing the indoor model. At the same time, the splicing method between the vertical and horizontal components in the later stage should be designed. The connection method of connecting column inserted into the reserved hole of the horizontal component at the bottom of the vertical component can be considered.If the later component still needs to be colored, it should be split according to the color block and the color operation space.

4. Delete the internal structure of the building model, and try to delete irrelevant display parts (such as furniture and some ornaments, etc.) without affecting the force, appearance and some details to be displayed. This can save costs and improve the efficiency of 3D printing.

The rapid development of 3D printing technology, 3D printing architectural models fast, low cost, environmental protection, and exquisite production, has a great advantage.Welcome to consult!

About us

We are a direct manufacturer with a professional design and production team.We have more than 15 years of experience in 3D printing and CNC machining industries.Our factory is located in Building 45, 40 Changbang Road, Songjiang District, Shanghai.Welcome to our company!

About products & services

We provide customers (including designers, researchers, engineers, students, medical workers, makers, etc.) with one-stop service from 3D scanning, 3D customized design to 3D printing and post-processing.

Our business scope includes 3D printer sales, 3D printing services, CNC machining, 3D modeling design, 3D scanning services, laser engraving, casting, mass die-opening production and other services.

Currently, printable materials include photosensitive resin, PLA, ABS, nylon, glass fiber, metal and ceramic, etc., which are widely used in rapid prototyping hand boards, automobile parts, building sand table model making, product development, design verification, key functional parts making, small batch production, etc.

About price

We are a manufacturer and have complete production machines and facilities as well as professional teams,so we can certainly make your budget lower. Besides,we can provide you some samples free of charge for your evaluation. Of course, if you can send us your sample, it will help us provide you more cost-effective solutions. Please feel free to tell us your detailed requirements.

About payment

T/T, L/C,Western union, Paypal are all available.

About delivery & shipment

3D-printed parts and CNC machining usually take 2-15 days by air, depending on size and order quantity.