Blog

The ultra-fast high-temperature sintering method can produce fine 3D printed structures by firing ceramics in 10 seconds

Scientists in the Department of Materials Science and Engineering (MSE) at the University of Maryland (UMD) have transformed a time-honored manufacturing process into a novel method for making ceramic materials that has promising applications in solid-state batteries, fuel cells, 3D printing and other industries.Ceramics are widely used in batteries, electronics and in extreme environments.But traditional ceramic sintering, the part of the sintering process used to make ceramic objects, typically takes hours of processing time.To overcome this challenge, a research team in Maryland has developed an ultra-fast high-temperature sintering process (called UHS) that can both meet the needs of modern ceramics and facilitate the discovery of innovative new materials.

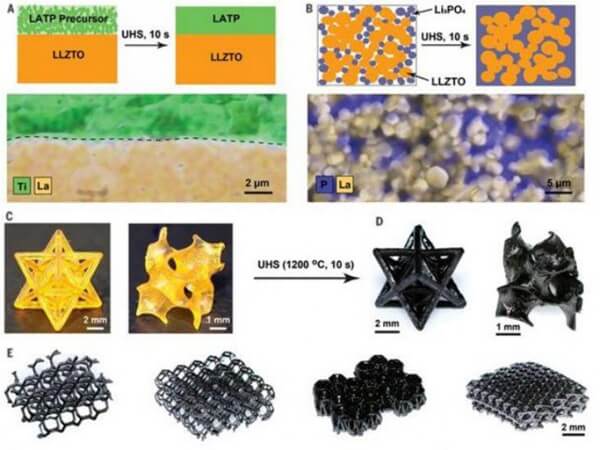

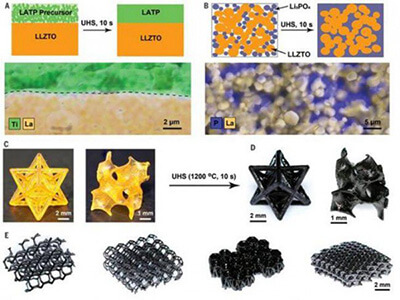

Figure: Structure realized by UHS sintering technology

The study on May 1, published in Science (Science) on the cover of the magazine, entitled “A general method to synthesize and sinter bulk ceramics in seconds”, by the university of Maryland professor Hu Liangbing, A professor, university of Virginia tech, professor at the university of California Zheng Xiaoyu and professor at the university of California, San Diego LuoJian team together (corresponding author).

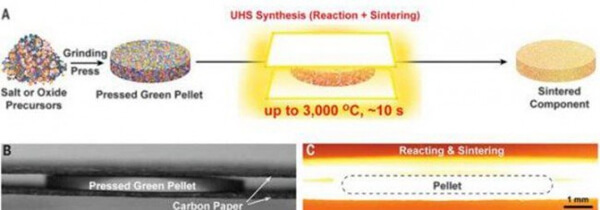

It is reported that some rapid sintering methods in the past have many limitations, such as too low temperature, time-consuming and energy consumption, high cost and other problems.The Maryland team’s new method of ultra-fast high-temperature sintering offers high heating and cooling rates, a uniform temperature distribution, and sintering temperatures up to 3,000 degrees Celsius.Taken together, these processes require a total treatment time of less than 10 seconds, more than 1,000 times faster than traditional furnace sintering methods.

“With this invention, we sandwicked a pressed raw ceramic precursor powder between two carbon strips and heated the particle rapidly through radiation and conduction, creating a uniform high temperature environment that forces the ceramic powder to solidify rapidly.””The temperature is high enough that you can basically sintered any ceramic material.The patented process can be extended to other materials besides ceramics.”According to the researchers, this approach is twofold: “Ultra-fast high-temperature sintering represents a breakthrough in ultra-fast sintering, not only because of its general applicability to a wide range of functional materials, but also because of its great potential for creating non-equilibrium bulk materials by retaining or generating additional defects.The technology is currently being commercialized by Hight-Tech LLC.”We are pleased to see that the pyrolysis time has been reduced from tens of hours to a few seconds, and that the fine 3D-printed structure has been retained after rapid sintering.”