Blog

DLP technology prints AlN ceramics

With high theoretical thermal conductivity (319 W/(m·K)), good electrical insulation, low thermal expansion coefficient and high mechanical strength, AlN is a promising ceramic material for radiator and microelectronics applications.The Chinese Academy of Sciences research team printed AlN ceramics based on DLP technology, which can produce small components with tiny structures, and investigated their thermal conductivity and mechanical properties.

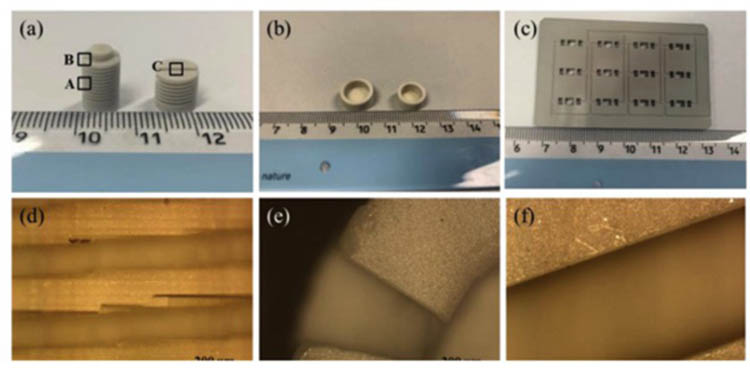

The research team dispersed AlN powder and Y2O3 powder in photosensitive resin, added thixotant and ball grinding to prepare ceramic paste with high solid phase and low viscosity of 55VOL %, degreased at 500℃, sintered at different temperatures between 1780℃ and 1845℃. Figure 1 shows the sintered part at 1845℃, and Figure 1 (a) shows two small parts with threads.It is evident from Figure 1 (d), (e) and (f) that micron-level threads and grooves with gradual and constant dimensions are available in these two small parts.The surface is smooth without burrs at the edge of the groove. Crucible and substrate with different sizes are shown in FIG. 1 (b) and (c).

FIG. 1 macro images and corresponding micro images of AlN ceramics :(a) small parts with threads, (b) crucibles of different sizes, (c) substrates, (d) a high-magnification image of a in (a), (e) b high-magnification image of b in (a) and (f) c in (a)

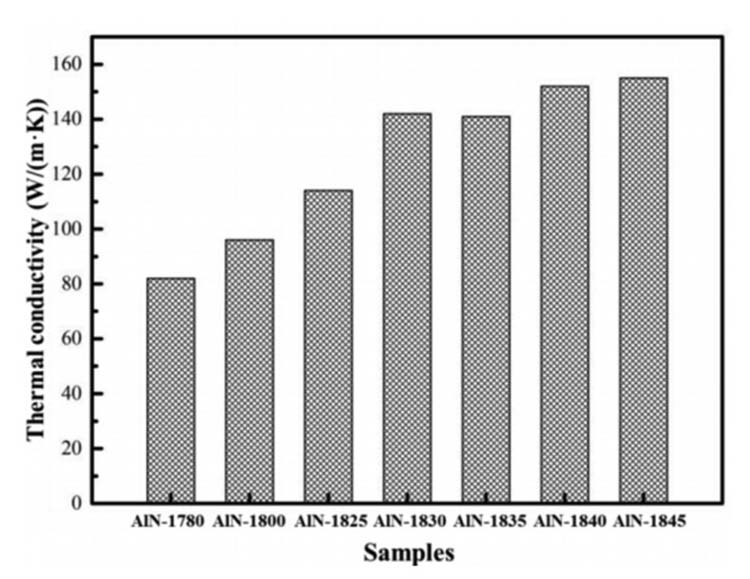

In Figure 2 (left), the thermal conductivity of AlN ceramics varies from 82 W/(m·K) to 155 W/(m·K), and increases with the increase of sintering temperature.With the increase of temperature, the density of samples increases and the porosity decreases.Therefore, the researchers conclude that the highest thermal conductivity of ALN-1845 can be attributed to significantly reduced grain boundary and point defects during densification.The bending strength ranges from 139MPa to 265 MPa and increases with increasing temperature.

Fig.3 Thermal conductivity of sintered AlN ceramics at different temperatures (left) Bending strength of sintered AlN ceramics at different temperatures (right)

In this paper, the research team used DLP technology and heat treatment technology to successfully realize the near-net forming of AlN ceramics with high thermal conductivity and high bending strength, and studied the effects of temperature on the phase transition, microstructure, thermal conductivity and bending properties of AlN ceramics.The method used in this work can be further applied to prepare other functional ceramics with complex shapes and has a broad application prospect.